|

The

block, cleaned, fitted with new core plugs, painted and mounted on the

stand, ready to start - |

|

First,

turn it over and check all the main bearing housings for burrs and

anything that will prevent the main caps from seating properly.

Chase out the

threads using plug taps (ones that will go all the way into blind holes -

non taper) |

|

Fit

the main bearing shells, I like to locate the tag on the shells into its

slot and press down the opposite side till the bearing is snug.

|

|

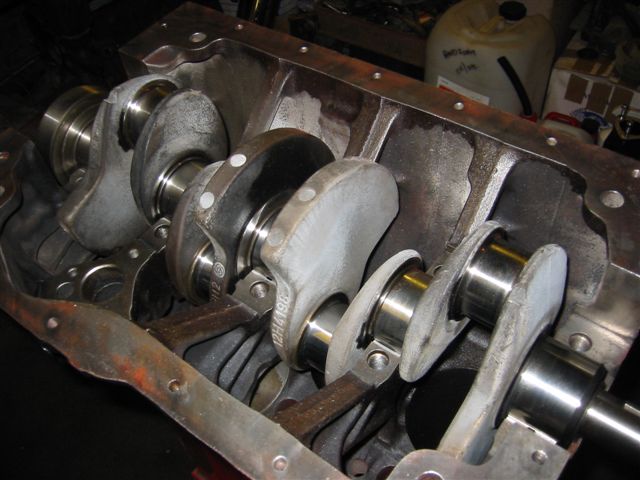

The

crank ready to fit - this one has been ground 10 thou on both mains and

big end journals - the thrust bearings are left standard. Note that the

rear of the crank where the rear oil seal fits has also been given a light

grind to remove the common groove - usually about 5 thou. |

|

After

checking the running clearances, a light coating of Graphogen is applied

to the shells...... |

|

....

and the crank gently set in the block.

|

|

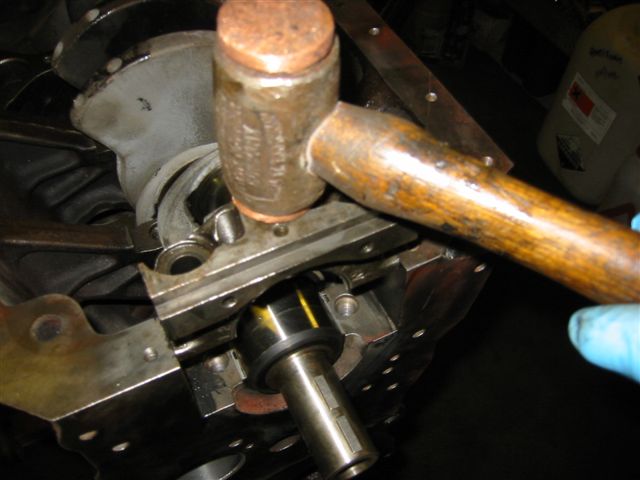

After

fitting the bearing shell into the cap and coating it with Graphogen, the

sides of the cap are also lightly coated and the cap driven into the block

with a copper hammer. |

|

Once

fully down, you can see that it is not flush with the front

face........... |

|

......

so light taps with the hammer, alternately on the front and top of the cap

drive it back until it is flush. |

|

The

same procedure on the rear cap.....

|

|

.......

down.......... |

|

......

and forward, till flush........ |

|

......

like this.

|

|

The

thrust washers (coated with Graphogen) are inserted either side of the

centre bearing - plain ones slide round the crank and the tabbed ones are

placed either side of the centre cap which is marked "front".

The number 2 and 4

caps are also marked "front" and "2" or "4"

on the area under the bolt head. |

|

Once

the caps are fully in place, the crank is tapped back ........ |

|

.......

and forward to centralise the centre cap and its thrust washers

..................

|

|

............

before fitting 10 new bolts ............. |

|

......

and torquing them up to 70 ft lbs.

After each cap is

tightened, check the crank is still free to turn - any stiffening needs to

be investigated and the cause rectified.

Next

section Back to

contents Back to Home page |